What is injection moulding and what are its benefits?

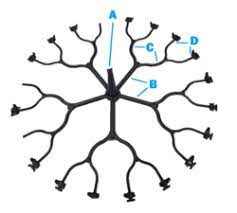

Injection moulding is the process by which various rubbers and plastics are heated to high temperatures, changing them into liquid form. They are then injected into a mould in which they are cured and vulcanised at a high temperature and under significant pressure.

Once cooled, they can be removed, having taken on the form of the mould which they will retain for their lifetime, or until such time as they are required to be recycled. At this point, they will again be heated to liquid and reused for another purpose.

Why choose injection moulding

Injection moulding is the ideal rubber moulding process for creating complex or intricate rubber components and can be used on a small scale or as part of a large automated manufacturing process.

Injection moulding produces a consistent outcome that is typically free from defects, perfectly cured and requires little to no trimming to achieve the desired shape. This makes the process very cost effective and reduces wastage in the manufacturing process. It is a good way of ensuring high quality and durability in the finished product.

The process is rapid, with a typical cycle time lasting between 15 and 30 seconds. This means that an enormous volume of products can be produced in an hour, making it very attractive to organisations wishing to create a bespoke run of products within a short timescale.

What industries use injection moulding

Injection moulding is commonly used to create seals, gaskets and tubing for the construction, automotive and agricultural industries. It can also be used to make specialist medical equipment for the pharmaceutical industry.

Injection moulding is a versatile and accessible process that is offered by many companies for a variety of industries where precision manufacture is required. Rubber products can provide soundproofing, reduce the effects of vibration and even comply with Food Quality Standards. Companies such as https://www.meadex.co.uk/rubber-moulding specialise in the process and can support clients in any industry, whether they require a bespoke low volume production or intend to mass produce their product through an automated manufacturing process.

Summary

Injection moulding is a reasonably cost effective process which can deliver uniform results, reduce wastage and is suitable for use across a wide range of industries. Those that are unsure about the best production process for their product should seek advice from a specialist supplier.